Molding Patterns (Casting Patterns)

Atra Co., equipped with design, manufacture and quality control components, declares its readiness for manufacturing molding patterns for almost all kind of mechanical parts.

The main activities of the Atra Company’s Modeling Group are as follows:

- Three-dimensional design of the part by the professional softwares.

- Three-dimensional scanning and preparation of point cloud files by scanner software and softwares such as Geomagic.

- Creating 3D files in design softwares such as Catia, SolidWorks.

- Creating a casting model in 3D designing software.

- Creating two dimensional drawings or generating G-Code file for CNC machines.

- Making a mold (casting) by wood or aluminum.

- Casting according to desired material.

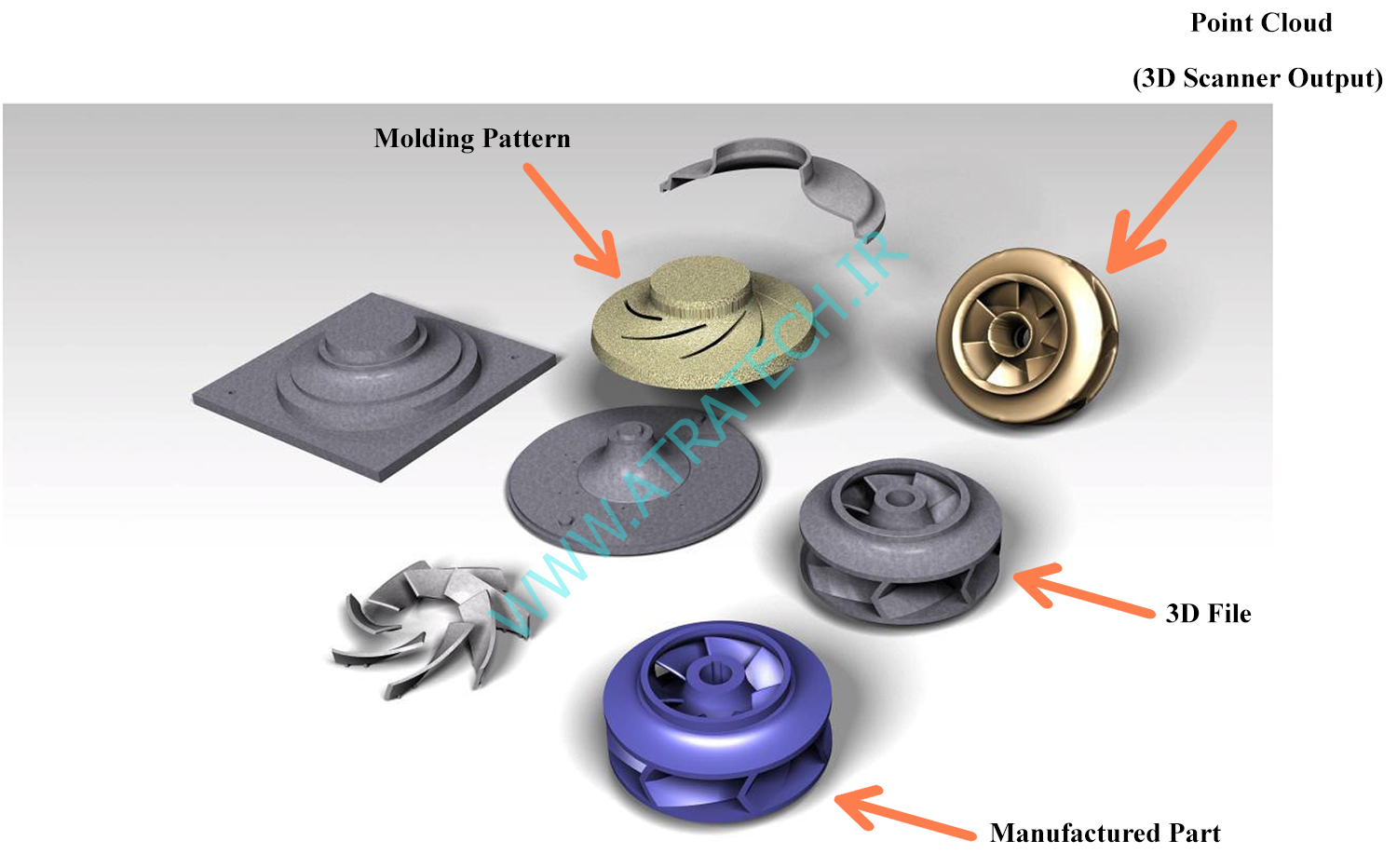

Manufacturing steps schematic view for a casting part (centrifugal pump impeller)

A notable point in designing casting models for molding is that the model should be made in such a way as to match the casting conditions. Since Atra Company has a vast experience in producing parts for casting, it is well aware of the requirements and limitations of molding, and so the models made by this company can easily be produced in factories and workshops that make molding manual and semi-automatic.

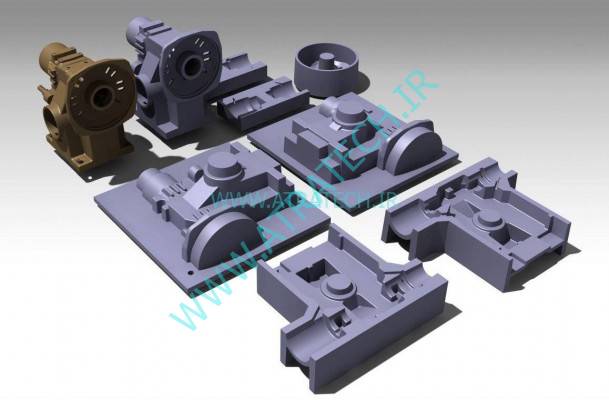

Schematic view of casting molds (Elevator Gearbox)

Schematic view of casting molds

- This unit with an experienced team and world class machines and instruments, manufacturers a variety of molding patterns, as follows:

Turbo-machinery components (all parts with molding pattern) - valve patterns

- Automotive parts

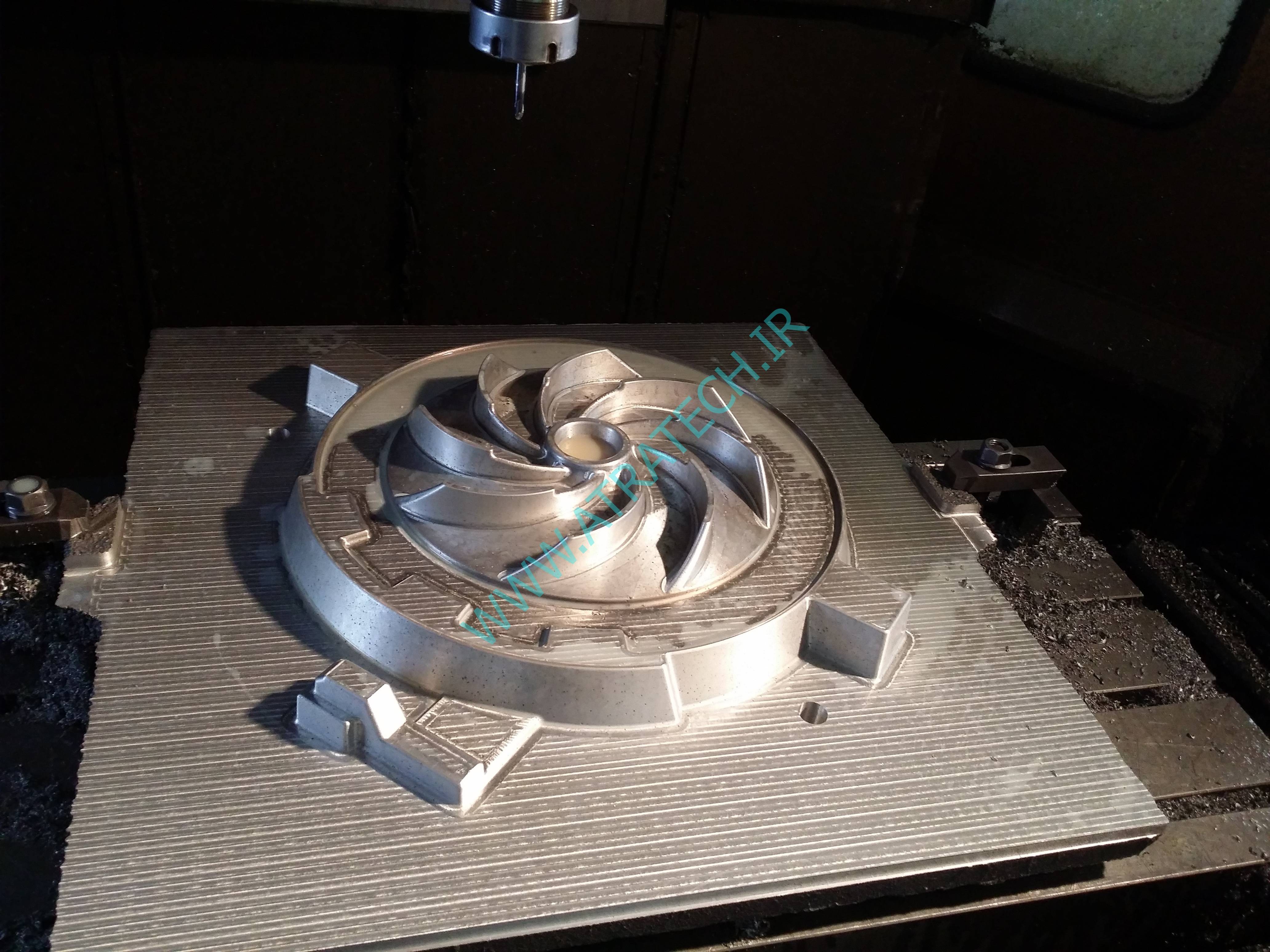

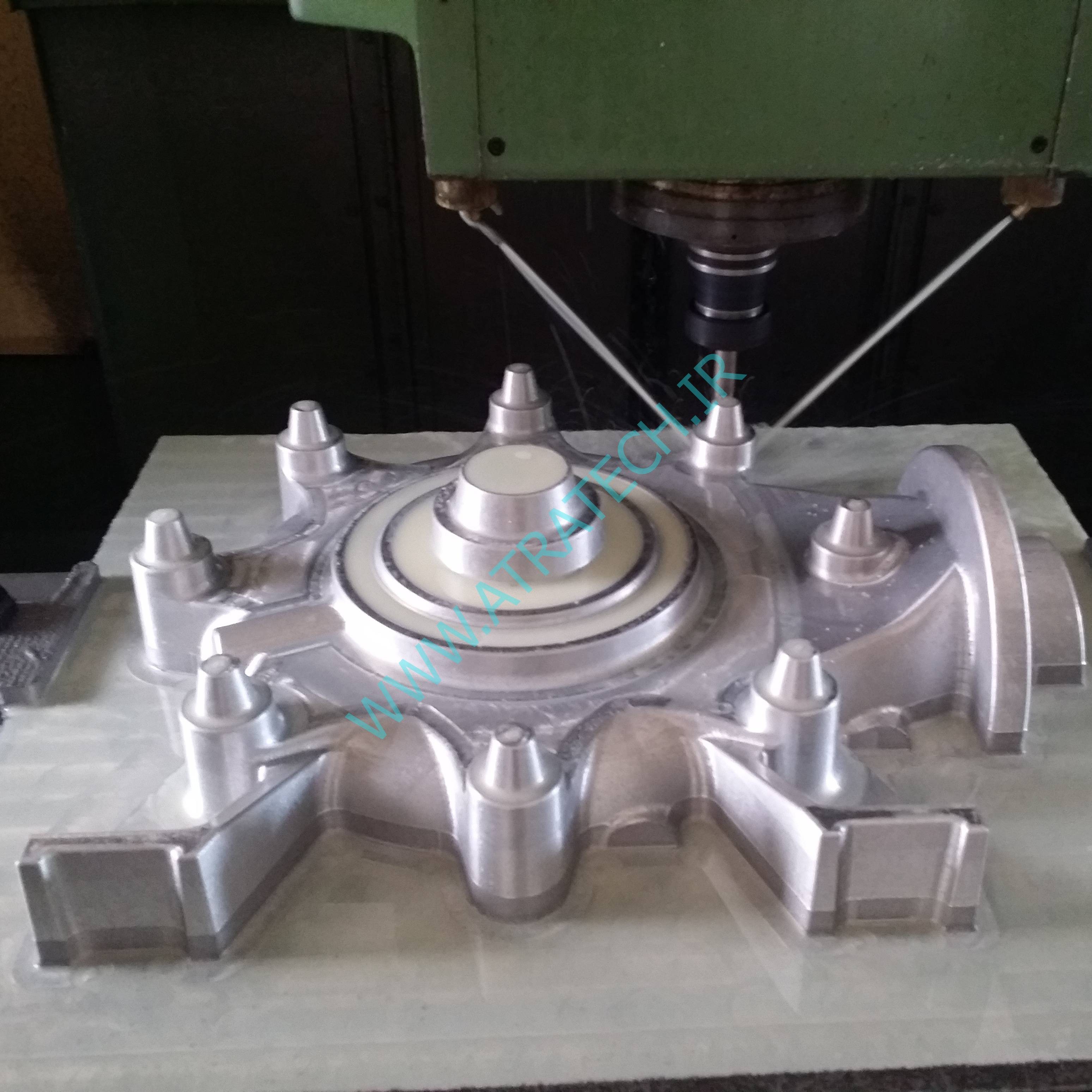

It should be noted that all stages of the preparation of the model are carried out in the company. The primary model is made of compact polystyrene foam or special wood for modeling by CNC machines. Then, using this cast aluminum model, it is manufactured and made the final model by CNC machines.

Molding pattern for a high pressure pump

Molding pattern for discharge casing of a multistage pump

دیدگاهتان را بنویسید