Reverse Engineering and Manufacturing Of Industrial Equipment

Atra Company has put one of its goals in the development of advanced technologies and the provision of up-to-date services for the manufacturing of industrial components. In this regard, one of the most important professional activities of the company is reverse engineering and manufacturing of industrial equipment. All stages of work, such as 3D scanning, computerized 3D modeling, manufacturing of parts and machinery, are carried out by the experienced staff of the Atra Group’s Modeling Team.

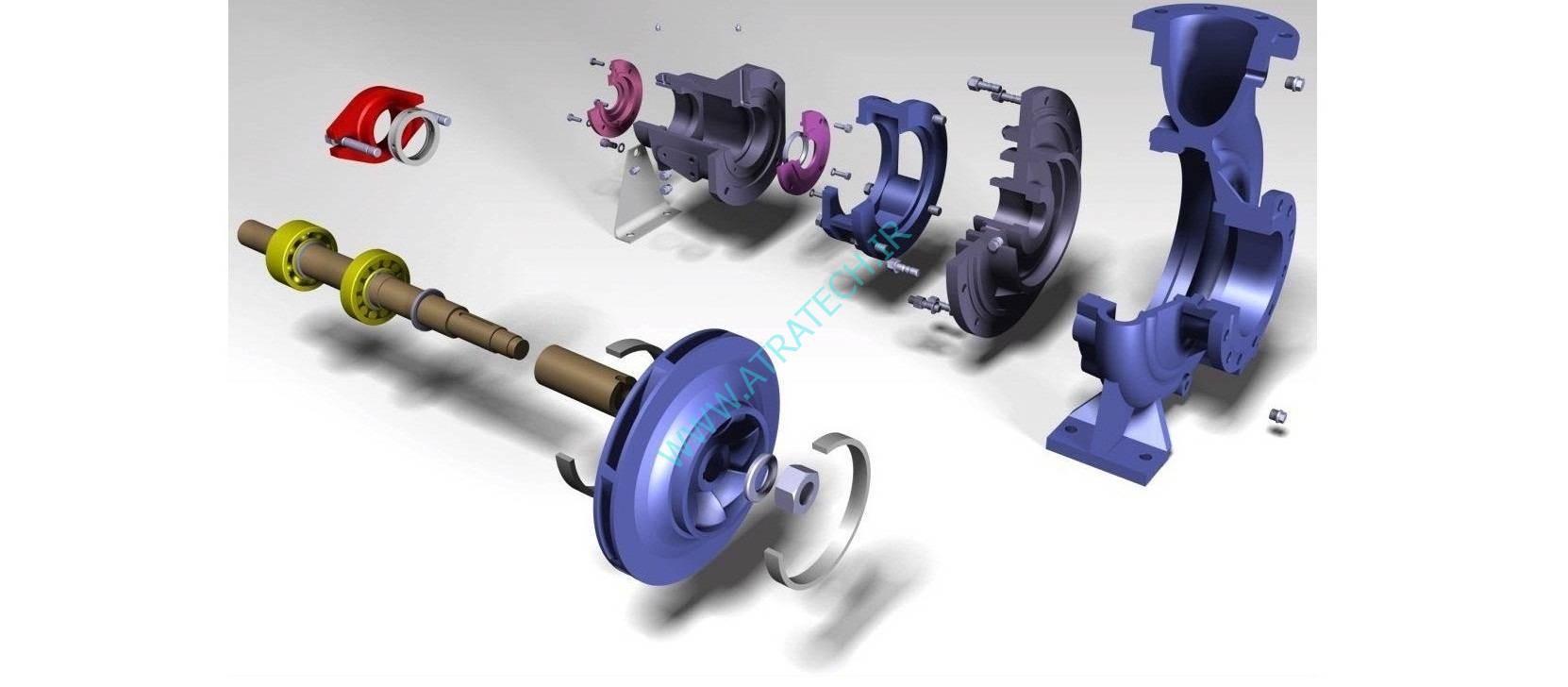

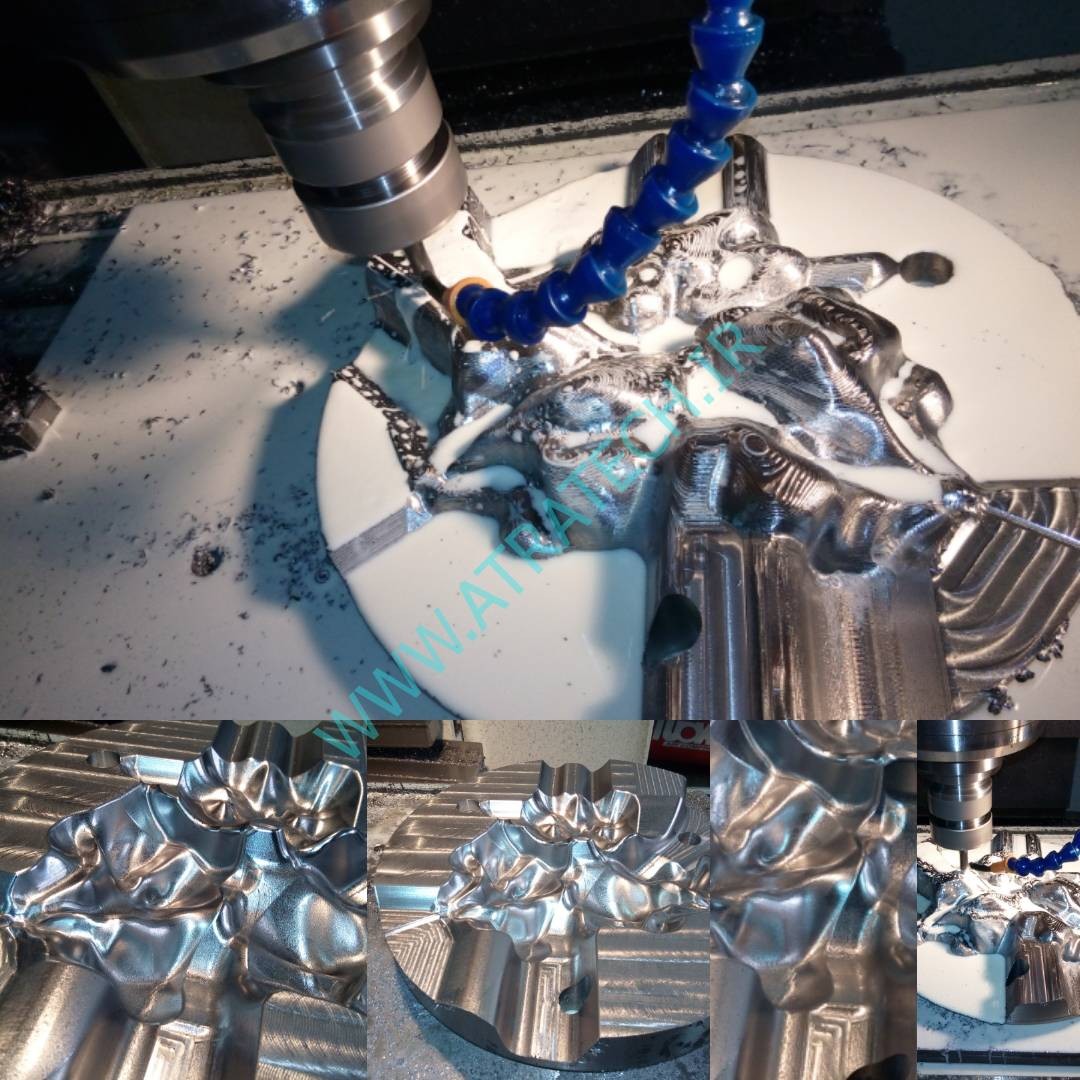

Reverse engineering and manufacturing of industrial centrifugal pumps in accordance with international standards

The steps of the reverse engineering process carried out at Atra Co. are as follows:

- Identification and Detection of System Components and Relations between Components in Machine Function (Parts)

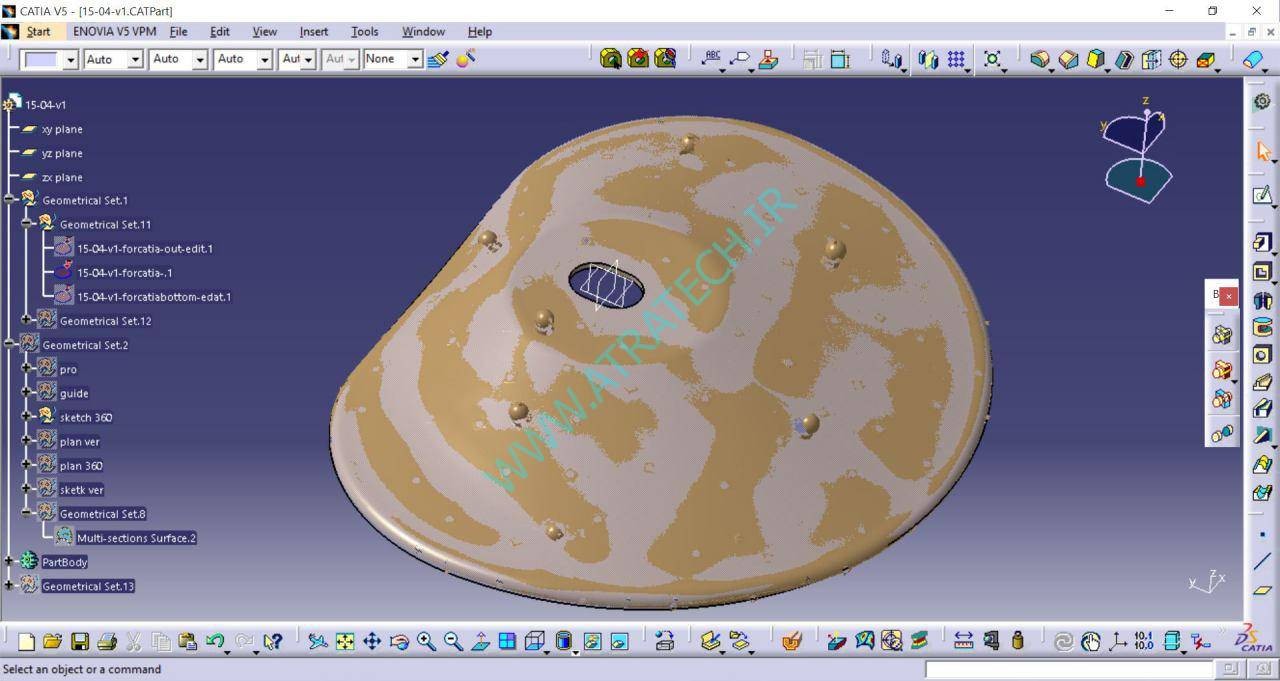

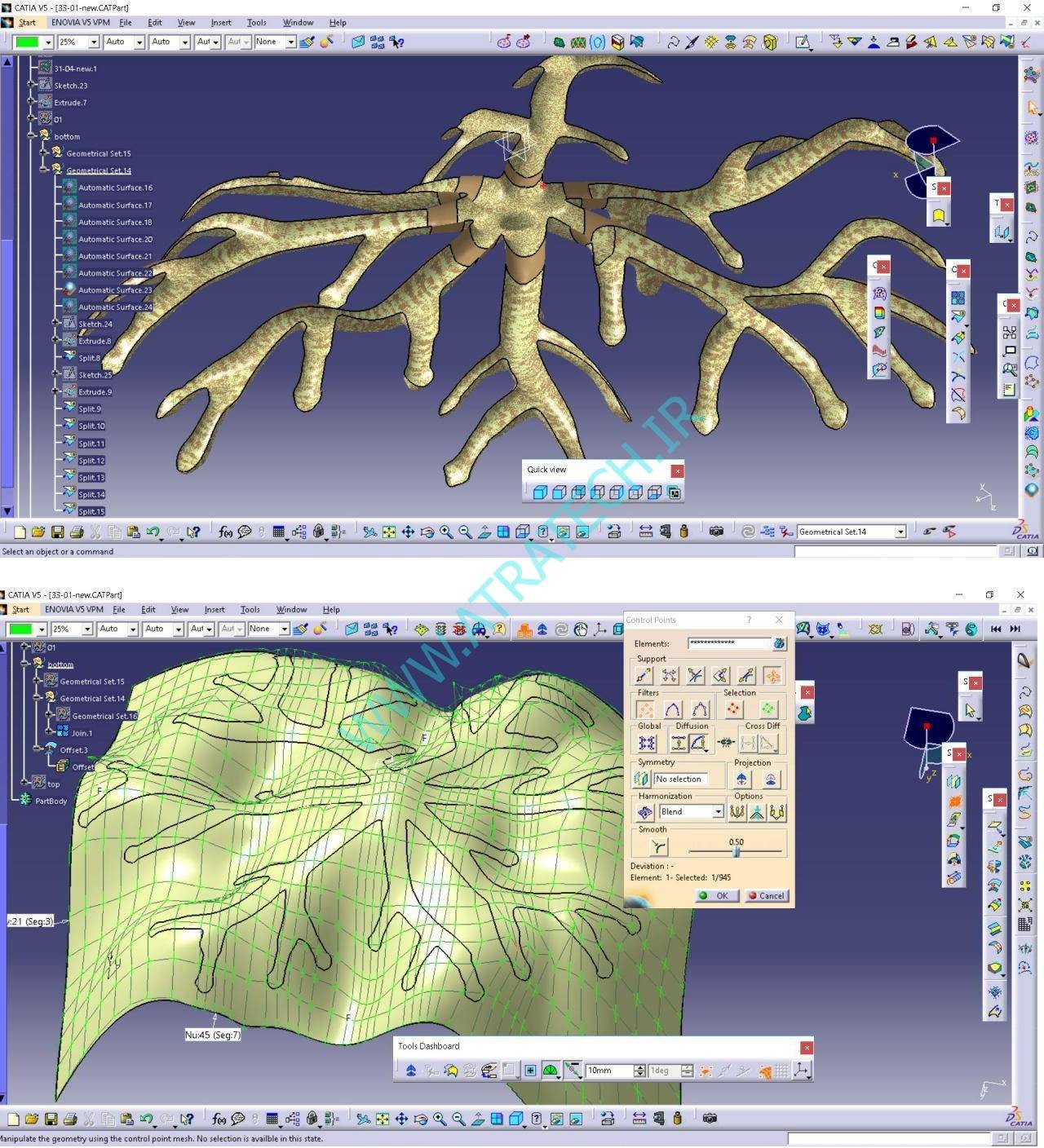

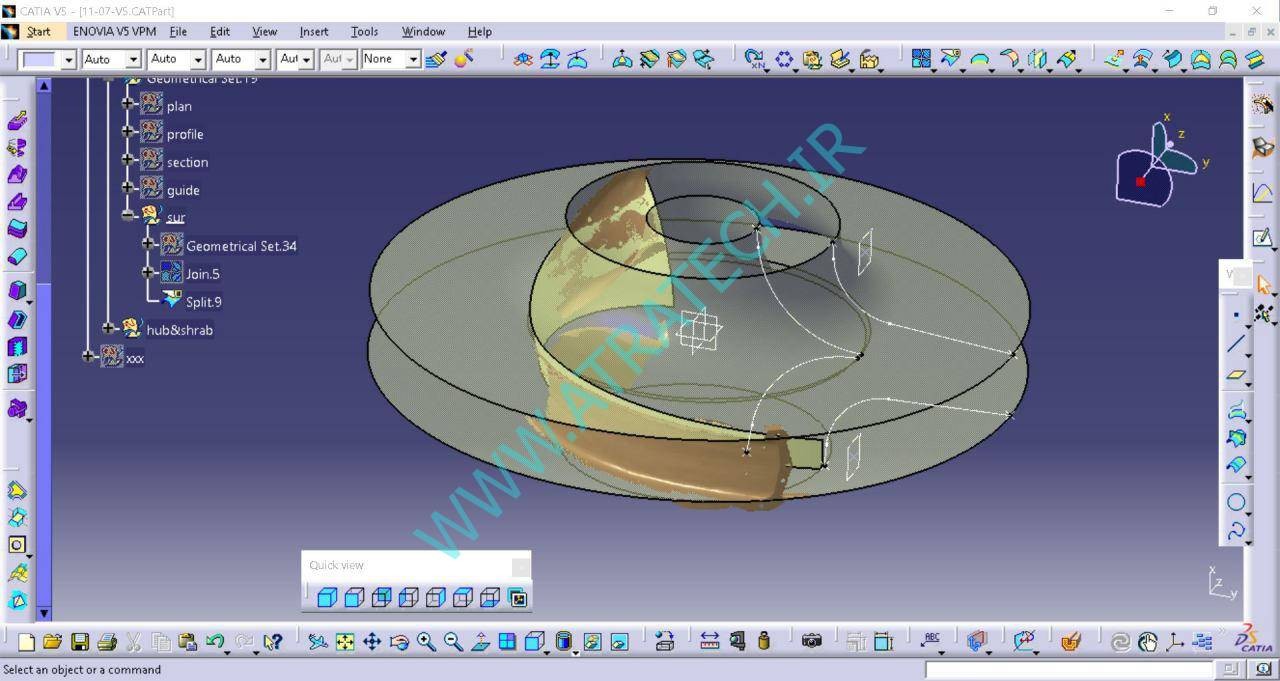

- Accurate measurement of parts and three-dimensional scanning of equipment with complex geometry

- Preparation of technical knowledge (three-dimensional model, manufacturing and machining drawings)

- Applying construction and assembly tolerances

- Determination the process of manufacturing of the parts or sets (machines)

- Quality control of parts by measuring instrument and optical scanner

Redesign and manufacturing of industrial parts and components (sheet metal)

3D scan of decortion parts (plastic tree)

Redesign of a centrifugal pump blade

Manufacturing of plastic injection mold (plastic tree)